OFFICIAL BOATING

LICENSE CANADA

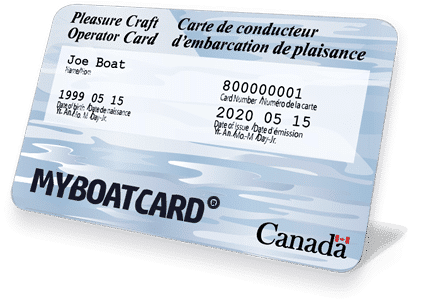

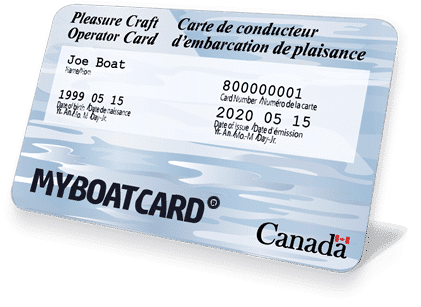

- Transport Canada - Pleasure Craft Operator Card ( PCOC )

- Free Course. Free Shipping.

- Card Never Expires. Valid Nationwide.

- Transport Canada - Operator Card

- Free Course. Free Shipping.

- Card Never Expires. Valid Nationwide.

- Now Only $39. Reg $59

Byron Kelly

Pro Wakeboarder, BC

Get Your Canadian Boat License in 3 Steps

CANADIAN BOATING LICENSE

Study. Pass. Print.

Study.Pass.Print.

MyBoatCard.com® provides the fastest and most affordable way to obtain your Canadian Boating License (PCOC).

Our easy-to-follow boater safety course and online boating exam are Transport Canada-approved.

The boating license never expires and is valid throughout Canada. Go boating today!

1

Study our Boating Course.

Study at your own pace.

Boating Course is free.

2

Pass the PCOC test.

Test is open book.

Retries are free and unlimited.

3

Print your Temp PCOC.

Go boating right away.

We ship your PCOC for free.

CANADIAN BOATING

LICENSE.

How do I get my Canadian boating license?

3 easy steps to get your Canadian boating license, also known as a Pleasure Craft Operator Card (PCOC):

- Study our easy-to-follow boating course. You can study at your own pace – your progress is tracked as you log in and out.

- Take the Official Transport Canada boating exam online. No need to worry – the exam is open book and our course includes everything you need to know to pass. Exam retries are free and unlimited.

- Print a temporary Pleasure Craft Operator Card (PCOC) at home and go boating straight away. Your permanent PCOC will be mailed out to you within 48 hours.

Do I need a boating license to drive a boat in Canada?

Anybody who operates a motorized recreational boat or jet ski in Canada must legally have proof of competency regardless of their age, engine horsepower or vessel length. The most common proof of competency in Canada is a Pleasure Craft Operator Card (PCOC).

Even if your boat is equipped with an electric trolling motor or a motor with less than 10hp, you still need a PCOC. The minimum fine for operating a boat without a PCOC in Canada is $250.

THE CARD

Pleasure Craft Operator Card (PCOC)

The PCOC is :

- Good for life. Never expires.

- Valid to operate any recreational boat.

- Valid for use throughout Canada.

- Valid for use in the United States.

- Shipped to you for free.

Free Chapter

Hours

Study Time

WHY US

MyBoatCard.com® is Canada’s trusted provider of boating safety education.

We aim to provide the best value and educational experience to all Canadians. We also guarantee the fastest shipping.

Join the more than 2 million certified Canadians.

FREE

COURSE

Free – Boating Safety Course

Free – Shipping + Handling

Free – Exam Retries

FAST

SHIPPING

We guarantee the fastest shipping.

We will ship your license within 48 hours.

Other providers take 4-6 weeks to ship!

100%

CANADIAN

We are 100% Canadian Owned.

OVER

2,000,000

CERTIFIED

CANADIANS

OVER

2,000,000

CERTIFIED

CANADIANS

How do I get a boating license in Canada?

How much is a Canadian boating license?

It costs $39 CAD to obtain a Canadian boating license. This one-time fee covers everything required to obtain the Pleasure Craft Operator Card (PCOC), including the:

- Boating safety course;

- Transport Canada PCOC exam (retries are Free and Unlimited);

- Temporary boating license (PCOC);

- Permanent boating license (PCOC); and

- Shipping and handling;

How long does it take to get a Canadian boating license?

It takes on average between 3 to 5 hours to obtain your Canadian boater license. The online boating safety course has a Transport Canada-required minimum study time of 3 hours and the Transport Canada PCOC exam has a maximum exam time of 1.5 hours.

After successfully completing the course and exam, you will immediately be issued a temporary Pleasure Craft Operator Card (PCOC) that you can print at home and use straight away. A permanent Pleasure Craft Operator Card (PCOC) will be shipped out to your address within 48 hours.

Does a Canadian boating license expire?

The Canadian Pleasure Craft Operator Card (PCOC), commonly known as a boating license, does not expire. Once you obtain your PCOC it’s good for life. There are no renewals or annual fees.

What is the fine for driving a boat without a license in Canada?

There is a minimum fine of $250 for operating a recreational-powered watercraft in Canada without a boating license (Pleasure Craft Operator Card) or other proof of competency.

TRANSPORT CANADA. APPROVED.

MyBoatCard.com® is Canada’s trusted provider of boating safety education and has been Transport Canada approved since 1999.

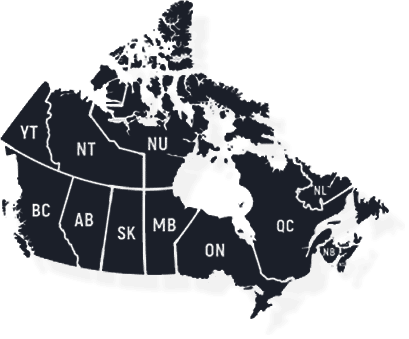

MyBoatCard.com® is accredited by Transport Canada issue Pleasure Craft Operator Cards (PCOC). The PCOC never expires and is valid in all Canadian provinces and territories including: Ontario, British Columbia, Alberta, Quebec, Manitoba, Saskatchewan, Nova Scotia, New Brunswick, Prince Edward Island, Newfoundland & Labrador, Nunavut, Northwest Territories, and the Yukon.

Join the more than 2,000,000 certified Canadians.

MyBoatCard.com® is Canada’s most trusted provider of boating safety education and has been Transport Canada approved since 1999.

Join the more than 2,000,000 certified Canadians.

Transport Canada

Ontario, Canada. K1A 0N8

EXPLORE

MyBoatCard.com® has been Canada’s trusted provider of boating education since 1999.

Providing the best value and educational experience to all Canadians.

Only $39

Reg $59

Free Online Course

Shipped in 48 Hours

Shipping is Free

Risk Free. Free Exam Retries

100% Canadian Owned

OTHER PROVIDER

$60

Reg $60

Pay Before Taking Course

Shipped in 4-6 weeks!

Charge for Shipping

Foreign Owned Company

BOATING LICENSE

FAQ.

What is a Pleasure Craft Operator Card (PCOC)?

Can I still get a Canadian boating license if I don’t have a driver's license?

What are the Transport Canada requirements for getting a boating license?

Transport Canada has no restrictions on who can obtain a Pleasure Craft Operator Card (PCOC).

- There is no minimum age requirement to obtain a PCOC

- You do not have to be a resident of Canada to obtain a PCOC.

Do I have to be a resident of Canada to take the boating safety course?

How long does the Canada boating license course take?

Is the Canadian boating license test hard?

No, the Canadian boating license test is not hard. MyBoatCard.com’s Transport Canada-approved boating course covers everything you need to know to pass the online boating license test.

The test is open-book and consists of 50 multiple-choice questions. The passing score is 75% (38 out of 50). If you fail don’t worry – exam retries are free and unlimited.

What age do I need to be to get a boating license in Canada?

There is no minimum age to obtain a Pleasure Craft Operator Card in Canada. As long as you are old enough to take the online boating safety course and pass the online exam you are old enough to obtain a Canadian boaters licence.

Boat operators of all ages, including those less than 16 years of age, are required by law to obtain and carry a Pleasure Craft Operator Card while boating.

Can you drive a boat without a license in Canada?

No. Anybody who operates a motorized recreational boat or jet ski in Canada must have proof of competency regardless of their age, engine horsepower or vessel length. The most common proof of competency in Canada is a Pleasure Craft Operator Card (PCOC), also known as a boating license.

What is the minimum age to drive a boat in Canada?

There is no minimum age to drive a motorized boat in Canada. According to Transport Canada’s – Vessel Operation Restriction Regulations (VORRs), children under 12 years old are legally allowed to operate a pleasure craft if it has a motor of no more than 10 hp (7.5 kW).

Horsepower restrictions apply to all operators under 16 years of age. Individuals aged 16 or older can operate a recreational vessel with any horsepower rating (including a personal watercraft (PWC)).

What is the biggest boat you can drive with a license in Canada?

In Canada, there is no limit to the size of the recreational boat you can operate with a Canadian boating license, also known as a Pleasure Craft Operator Card (PCOC). For example, with a PCOC you can legally operate a 300ft recreational yacht.

What is the biggest boat you can drive without a license in Canada?

You legally can not operate any powered watercraft in Canada, regardless of motors power or size, without a boating license (PCOC) or other proof of competency.

Is my Canadian boating license valid in all provinces?

Yes – the Pleasure Craft Operator Card is valid in all Canadian provinces and territories.

For more information on a specific region, please refer to the province and city pages:

Is my Canadian boating license valid in the United States?

Yes – the Canadian Pleasure Craft Operator Card (PCOC) is recognized in the United States as equivalent to their NASBLA-accredited Boating Safety Education Certificates. Therefore, Canadian boaters who have completed their boating safety course and obtained a PCOC can operate a vessel in U.S. waters without additional certification.

How long does it take to receive my boating license in Canada?

The online course and exam take on average 3 to 5 hours to complete. You will receive your temporary Pleasure Craft Operator Card (PCOC) immediately after you passed the Transport Canada boating license exam.

You can print your temporary boating license at home and go boating straight away. The temporary PCOC expires 60 days from the date you passed the test. MyBoatCard.com® will manufacture and ship out your permanent PCOC within 48 hours.

What happens if I lose my Canadian boater license?

If you lose or damage your boater license, also known as a Pleasure Craft Operator Card (PCOC), simply click here to order a replacement card. Once your order has been processed, you will immediately receive a temporary replacement PCOC to print at home so you can go boating straight away. Your permanent replacement PCOC will be shipped out to you within 48 hours.

Do I need a license to drive a jet ski in Canada?

All Personal Watercraft (PWC) operators in Canada must have a boating license or other proof of competency to operate a PWC. The Canadian Boating License, also known as a Pleasure Craft Operator Card (PCOC), is required for all ages, type of watercraft and engine power.

All PWC operators must carry their PCOC with them at all times when operating a PWC in Canada. Failure to have your Pleasure Craft Operator Card with you when jet skiing could result in a minimum fine of $250.

Do I need a license to rent a boat or jet ski in Canada?

No, you do not need a license, also known as a Pleasure Craft Operator Card (PCOC), to rent a boat or jet ski (PWC) in Canada.

Transport Canada allows you to rent a boat or jet ski in Canada without a boating license if you have completed and co-signed a Rental Safety Checklist with the rental company.

What is a Pleasure Craft?

In Canada, a Pleasure Craft refers to any boat or watercraft used exclusively for recreational purposes.

Is the MyBoatCard.com® course approved by the Transport Canada?

Yes. MyBoatCard.com® is accredited by Transport Canada to deliver the boating safety course and administer tests for the issuance of Pleasure Craft Operator Cards, including replacement cards, under the Competency of Operators of Pleasure Craft Regulations.

Is there any more information available on the Canadian boating license?

TRY IT. FREE.

Transport Canada approved Boating Safety Course is free.

Take the course in your own time and risk-free.

Other providers try to get you to pay upfront before you even have a chance to try out their course!

WHY WAIT. WEEKS.

MyBoatCard.com® guarantees the fastest shipping. Your boating license (PCOC) is manufactured and shipped out in under 48 hours.

Other providers take between 4 to 6 weeks to ship your card.

REVIEWS.

FREE

BOATING License Practice Test.

Looking to get your Canadian boater’s license and not sure what to expect from the Transport Canada test. MyBoatCard.com® provides a practice test for free, so you can test your boating knowledge before you start the online course and take the Transport Canada exam.

- Free Practice Test

- The Exam is Open Book

- Exam Retries are Free

BOATER License

Study Guide.

To obtain your Pleasure Craft Operators Card, you will start by taking the online boating safety course.

The boating safety course covers topics such as : boating terminology, boating safety equipment, navigation and emergency preparedness.

You can download and print the boating safety course material in a study guide, if you prefer to have something in your hand to read while completing the course and taking the exam.

Canadian Boating License Study Guide

Boating-License-Study-Guide.pdf

NO.

ROADS.

BE FREE.

Go Boating Today.

WHY PAY. MORE.

MyBoatCard.com® was established to provide you with the most affordable and fastest way to obtain your Canadian boating license. We are 100% Canadian-owned.

Purchase your official boating license for only $39.

One-time fee. The card never expires.

ANY DEVICE. ANY WHERE.

MyBoatCard.com® online boating safety course is fully mobile-friendly from start to finish. The boating safety course has been designed to work on your smartphone, tablet, laptop, or desktop computer.

MyBoatCard.com® automatically keeps track of your progress, so you can study at your own pace.

BOATING. IN CANADA.

Canada is a boating paradise. Not only is Canada the second largest country in the world but it is also home to the longest coastline in the world, with over 202,080 km of coastline. Canada is also home to 50% of the world’s natural lakes (31,752 lakes). Canadians are spoilt for choice of where to explore by boat.

Both residents and non-residents of Canada must follow Transport Canada’s boating regulations, which emphasize safe operation and environmental protection. The most important of these is regulations is the Operator Competency requirement.

This rule requires anyone operating a motorized pleasure craft to have proof of competency, such as a Pleasure Craft Operator Card (PCOC), on board.

Non-residents must comply if they either use their boat in Canadian waters for over 45 days or operate a boat registered or rented in Canada. However, those using their own boat for less than 45 days in Canada only need to show proof of residence, not a PCOC.

BOATING. LAWS.

The Canada Shipping Act, of 2001 is the principal legislation governing the safety of marine transportation and recreational boating, as well as protection of the marine environment in Canada.

The act lays out laws and regulations, including the requirement that all boat operators must have a Pleasure Craft Operator Card or other form of proof of competency. The objective of this requirement is to enhance boating safety and to decrease the incidence of boating-related accidents and deaths.